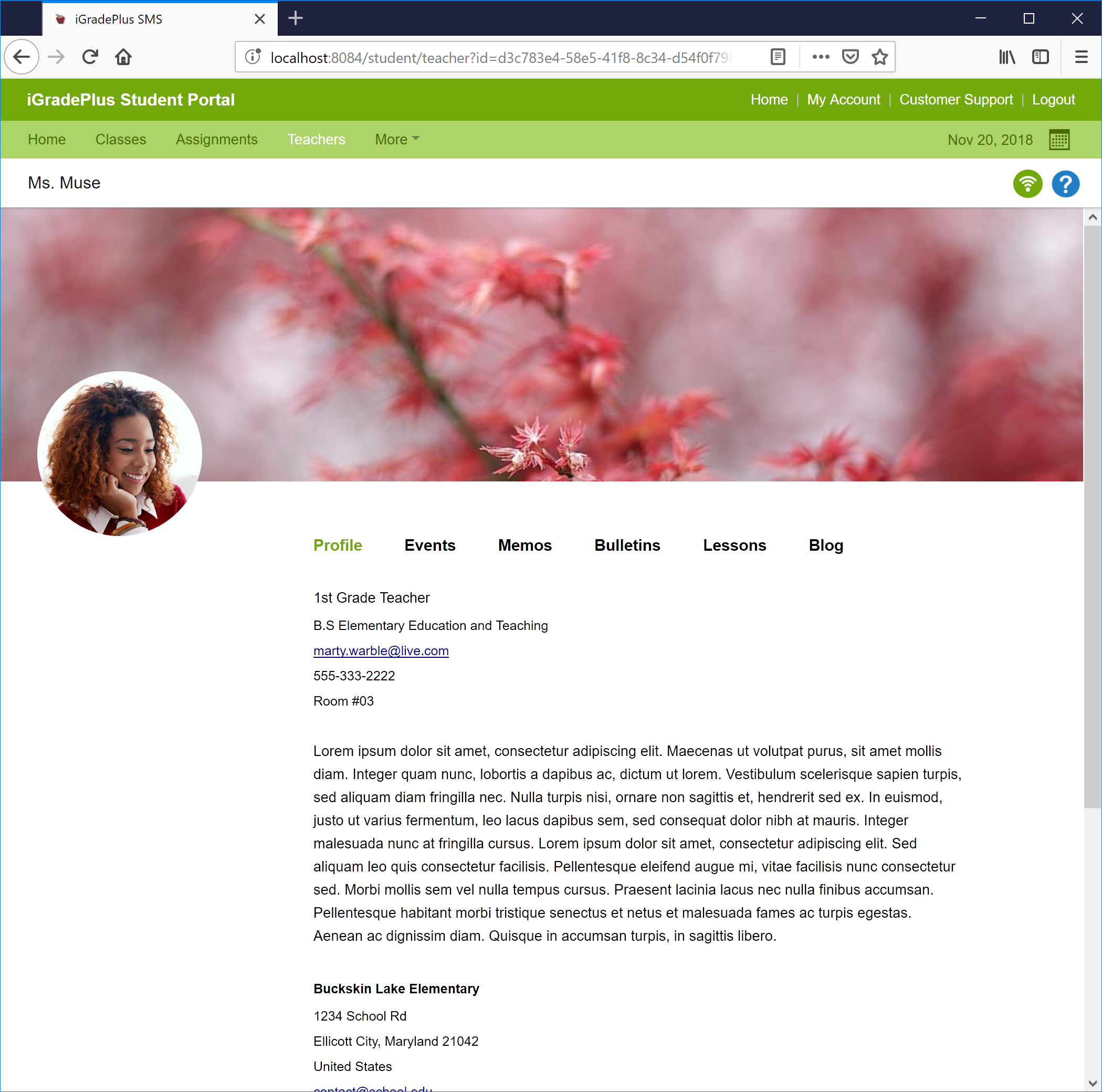

We also let you check their overall scores to know which one seems to be better. You can examine the specifics, for example available tools, pricing, plans offered by each vendor, offer conditions, and many more This means that your enterprise can get the most productive and efficient program. Injected into the skin must be surgically removed withinĪ few hours or gangrene may result.What is better iGradePlus or Together Mentorship Software? When comparing iGradePlus and Together Mentorship Software, you can actually see which Learning Management System - LMS product is the more suitable choice.

Moline, Illinois, U.S.A., by calling 1-80 or +1 If an accident occurs, see a doctor immediately. Such information is available inĮnglish from Deere & Company Medical Department in Search for leaks with a piece of cardboard. With this type of injury should reference a knowledgeable With John Deere approved replacement parts.Įscaping fluid under pressure can penetrate the skinĪvoid the hazard by relieving pressure beforeĭisconnecting hydraulic or other lines. Replace worn or damaged hose assemblies immediately Inspect hydraulic hoses periodically – at least once per year – for leakage, kinking, cuts, cracks, abrasion,īlisters, corrosion, exposed wire braid or any other signs of wear or damage. Stop operation if poor visibility conditions impair your ability to operate the machine or identify people or obstacles in the machine path.Take control of the machine, when necessary, to avoid field hazards, bystanders, equipment, or other obstacles.Remain alert and pay attention to the surrounding environment.Verify the machine, implement, and automation systems are set up correctly.To prevent injury to the operator and bystanders: This includes, but may not be limited to, iGrade™ and Active Implement Guidance. Implement automation systems include any application that automates implement movement. The operator is always responsible for the machine path. Implement automation systems are intended to aid the operator in performing field operations more efficiently.

On (activate) an implement automation system while transporting on a roadway. Always turn off (disable) implement automation systems before entering a roadway. Two people are required when mounting locations are not accessible from the ground or from a service platform.ĭo not use implement automation systems on roadways. The mast is heavy and can be awkward to handle. If installing or servicing a global positioning receiver mast used on an implement, use proper lifting techniques and wear proper protective equipment. If installing or servicing a RTK base station on a tower or other tall structure, use a certified climber. Do not install or remove components in wet or icy conditions. Use sturdy and secure footholds and handholds. Use a ladder or platform to easily reach each mounting location. Handle Electronic Components and Bracketsįalling while installing or removing electronic components mounted on equipment can cause serious injury. Use extra care when mud, snow, or moisture present Maintain 3-point contact with steps, handholds, and Prevent falls by facing the machine when getting on and Tractor before servicing electrical system components or On towed implements, disconnect wiring harnesses from On self-propelled equipment, disconnect battery groundĬable (-) before making adjustments on electrical systems Remove any buildup of grease, oil, or debris. Keep all parts in good condition and properly installed.įix damage immediately. Securely support any machine elements that must be Disengage all power and operate controls to relieve Keep hands, feet, and clothing from power-driven Never lubricate, service, or adjust machine while it is Understand service procedure before doing work. Īdjusting Trip Cycle.ĭisconnect iGrade™ System. Īdjust Valve.Ĭalibrate SCV Thresholds.īasic Operation.Įngage iGrade™.ĭual Scrapers.

Understand Signal Words.įollow Safety Instructions. John Deere Service Keeps You on The Job.John Deere Service Literature Available.Configure SCVs On CommandCenter™ - Auto Mode.

0 kommentar(er)

0 kommentar(er)